Hi everyone! My name is Amber and I am the owner of Ísponica, a newly-established vertical farm in Hólar, Iceland. I‘m originally from the Savannah, Georgia area. I‘ve been living here in Iceland since 2018, which is when I started my MSc at Hólar University, where I studied lumpfish. If you don‘t know what they are, they‘re a beautiful blue saltwater fish and you should check them out!

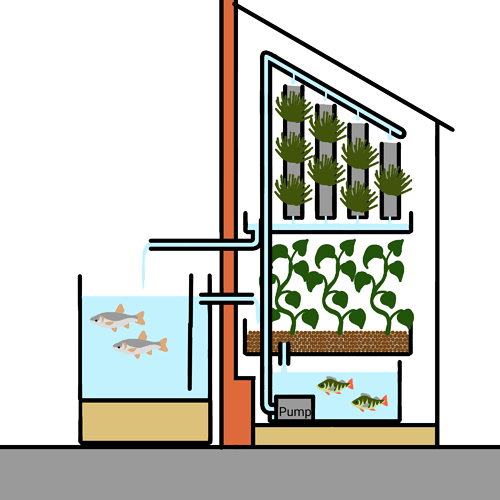

It‘s always been a dream of mine to become an aquaponic farmer. I knew after I finished my MSc in June of this year I wanted to do this for a living, so I began the process of creating Ísponica. The small village of Hólar holds a special place in my heart and I knew that this would be the perfect place to found the farm. One building in particular caught my attention – it is an old cow barn (you can see it in the photos) that has mostly been used for storage for at least the last 10 years or so. The building has also held many other things over the years – animals, a public aquarium, an apartment, and is currently home to our local pub and brewery. The original cow barn was built in 1914. Historical reports say it was considered the best cow house in northern Iceland when it was built. In 1948, the barn was renovated and added onto to increase the size of the building (Ísponica is now located in the newer part of the building). The silos you can see in the picture were built in 1950. The room where Ísponica is being set up used to be the public aquarium, which worked out perfectly as the old aquariums, pipework, and electrical were still in place. It was possible to re-purpose a lot of the aquarium setups and metal stands to use for plant grow racks, which is a big help to a small startup like this one.

Ísponica is starting out in the basement area (about 94 sq meters or around 1012 sq feet). My hope is that Ísponica does well and can grow into the second floor of the barn, which is even larger (about 294 sq meters or 3165 sq feet). The oldest part of the building (the original barn built in 1914, which is not counted in the second floor area) is around 97 sq meters or 1044 sq feet. The second floor of the barn needs some renovation, but there is so much potential in this building for Ísponica to grow into. I love that a new agricultural chapter is being written into its history.

Being in the rural area of Skagafjörður in northern Iceland, it can be tricky at times with fresh produce because most of it needs to be transported to us (whether from somewhere else in Iceland or from abroad). Ísponica will be able to grow year-round, which means locals will have direct access to its products regardless of weather conditions and seasons. While the snow is beautiful, it gets cold and dark during the winter in Iceland, you know!

The goal is to start out with microgreens and lettuce. I have also been asked about producing mushrooms and sprouts, which aren‘t necessarily grown aquaponically, but it will be a fun challenge to provide different food options for customers. I currently have some tilapia (not for eating) and goldfish to start off with. Hopefully in the next few years I can shift over to a system where I can grow fish to harvest for customers.

You can see in the photos I’m still going through the setup process but things are moving along. Growth trials will begin in the near future – if you‘re interested in keeping up with the progress, you can follow the Facebook page Ísponica (@isponicaverticalfarm) and Instagram (@isponicavf). The website will be made public soon.

Happy growing and I wish you healthy greens wherever you are!

Cheers,

Amber